Crew Energy Testimonial on the KWAT

“Crew Energy utilized the WACORP KWAT tool during our abandonment operations. The pressure test was achieved in a single wireline run and saved an estimated 5 hours in tubing trip and pressure test time. The objective to abandon the completed interval was completed 0.5 days earlier and saved approximately $8,000 in service rig, supervision, rentals and other auxiliary costs.”

Nick Kozak – Completions Engineer

Shell Testimonial on the KWAT

“We recently utilized the KWAT to set and pressure test an abandonment plug above the lower set of perforations in a two zone well in Northeast BC. Being able to do this on wireline allowed us to move our rig to another job a day earlier than planned and also saved us over $10k/30% compared to doing this the conventional way on tubing. Considering the number of legacy wells that we need to abandon in the near future with dual completions and/or minor casing leaks, integrating this tool into our abandonment practices is going to result in significant cost and time savings.”

Dustin Pashko – Shell Canada Abandonment Focal

Crescent Point successfully uses multizone abandonment tool to set and pressure test barriers in a single run

K-WAT tool reduces the cost of well abandonment

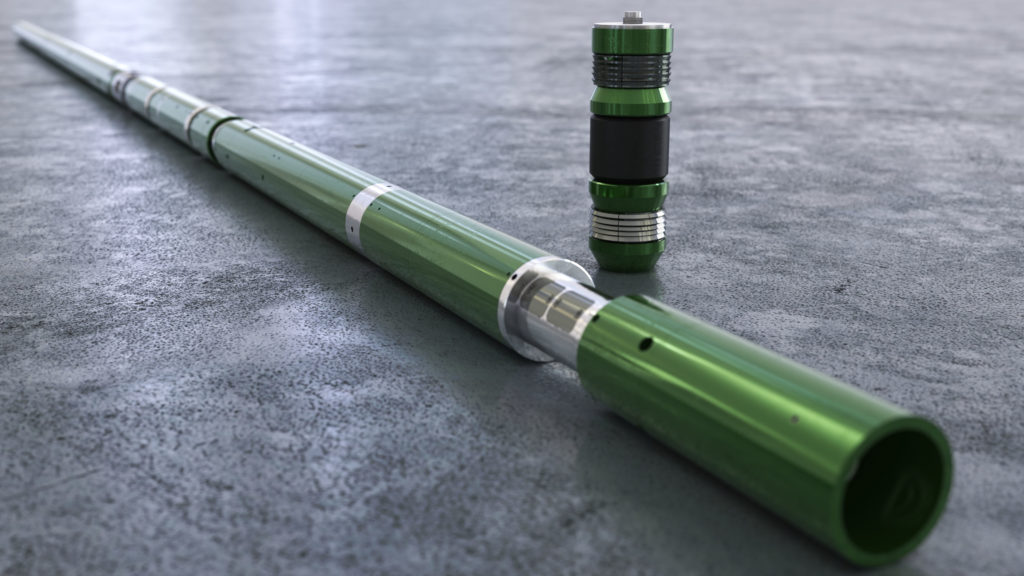

Wireline Abandonment and Completion Corp. (WACORP) announces Crescent Point Energy’s successful utilization of WACORP’s wireline-deployed K-WAT tool in Alliance and Turner Valley, Alberta in a five-well, 14-zone well abandonment pilot project, to satisfy the Alberta Energy Regulator (AER) oil and gas Well Abandonment Directive 20.

From Nov. 30 – Dec. 18, 2021, in temperatures that dipped to – 29 C, Crescent Point Energy conducted a comparison of pressure testing at the target, compared to a full column of fluid pressure test from surface +7 MPa. Crescent Point provided exceptional candidates, with two to four zones per well with a maximum working depth of 1,489 meters. Run times were continuous between K-WAT and dump bailing with less than five minutes to lay down and pickup. No explosives were required to set the plug, as the patented K-WAT system is fully hydraulic.

Pressure below and above the tool is monitored continuously, yielding both a digital and paper record of the entire process for confirmation and regulatory board submission of the pressure test.

Many companies have an increasing number of uneconomical wells. There is significant demand for zonal abandonment of suspended wells. The K-WAT tool’s ability to set and pressure test barriers simultaneously is an industry first, paving the way forward for rigless abandonment technology.

“This is a technological breakthrough,” says WACORP president, Peter Knight. “Our hybrid tool instantly generates pressure at the downhole target. It reads out on surface and completely eliminates the traditional operation. This is the only tool in the world that can do this. It’s a complete process change from the conventional abandonment procedure. It’s the speed you can work with and the efficiency you can create by utilizing it, versus service rigs and coil. It simplifies the complexity of the pressure test.”

“Crescent Point and other oil and gas companies are actively looking for cost savings and economic solutions to these abandonments,” Knight says. “With the K-WAT tool, we now have the technical advancement to make these types of problem wells economical and affordable and get them off their books.

“By supporting this project, Crescent Point has shown the industry they are a true leader in the development of new and cost-saving technology. Crescent Point has helped the whole industry by taking part in this pilot to commercialize it.”

Conventional multi-zone abandonments require a tubing packer run, necessitating the use of a coil tubing unit or service rig. Our system, on the other hand, allows for wireline-only multi-zone abandonments by simultaneously setting and pressure testing the bridge plug on wireline. The K-WAT tool sets and pressure tests the bridge plug, eliminating the costly tubing run. The K-WAT tool can save as much as 50% in both time and expenses, compared to current multistage abandonment practices.

This tool means that organizations specializing in the abandonment and reclamation of oil and gas well sites can carry out abandonment operations using only a wireline truck. Reducing the number of services required on site for any given application lessens the safety risks for all individuals involved during tubing trips and pressure test, and also lowers the carbon footprint.

This greatly reduces emissions, by lowering the amount of equipment and days needed to complete abandonment procedures. Ultimately, the potential savings for oil companies, and taxpayers, are tremendous.

K-WAT tool benefits include:

- Smaller footprint;

- Increased well abandonment efficiency (up to three times);

- Noise pollution reduction 45%;

- Safety incident reduction 50%;

- Man-hour reduction 70%;

- Fuel consumption reduction 80%;

- Eliminates trucking, work strings, rental and standby costs;

- No explosives required.

“The energy regulator is excited about technologies like this that can set and pressure test barriers without the need for a service rig,” Knight says. “They see the digital pressure test as the way forward for proper compliance. With this technology, you have 100 per cent proof that on that day at that depth, this plug was pressure tested properly.”

“It’s important to develop technology that’s going to lower the overall cost of abandonment. With the K-WAT tool, we have the technical advancement to make these types of problem wells economical and affordable to get the off their books.”

The Crescent Point Energy project was part of a 10-well pilot that is now nearing completion. WACORP is now moving into Generation 1.5, with the K-WAT tool as a fully proven field system. It will eliminate dependency on wellbore fluids to set the plug, with an onboard fluid reservoir allowing the tool to work reliably in unstable fluid columns. “It allows us to work in unstable fluid environments by fully onboarding the fluid that we use to function the tool,” Knight explains. “We’ve eliminated the difficulties and complexities of the conventional well abandonment operation.”

Peter Knight founded Wireline Abandonment and Completion Corp. (WACORP) in 2016 to streamline the abandonment of oil and gas wells in Alberta.

For more information, contact Peter at 1-403-988-9758 or peter@wacorp.ca

WACORP successfully trials E-line deployed multizone abandonment tool on Shell Canada abandonment site.

WACORP (Wireline Abandonment and Completion Corp.) is pleased to announce the successful trial of the new and patented KWAT tool in Dawson Creek, Alberta with Shell Canada. Based on the results of this trial Shell has indicated that the KWAT technology meets and exceeds their internal and provincial regulatory compliance requirements to abandon their multizone wellbores.

According to the Alberta Energy Regulator, the province has approximately 95,000 inactive and an increasingly growing number of orphan wells. The KWAT tool is a novel abandonment technology that allows operators to plug multizone wellbores cutting nearly 40% the cost of traditional abandonment operations using E-line. The tool equips operators with an effective and reliable system that accurately logs into position, sets and pressure tests each barrier prior to capping with cement.

Peter Knight, president of WACORP states “This technology offers enormous savings in both rig time and rig costs throughout the entire operation compared to rigging in with a service or coil rig. This new tool drastically lowers operator expenses and time spent on each well while providing a much smaller operational footprint. This is not only good for the environment, but also provides a safe and more economical way to tackle this massive abandonment challenge. Operators and regulatory bodies now have a proven solution to abandon complex and deep wellbores with greater efficiency at a much lower cost.”

The system functions by utilizing wellbore fluid for hydraulic operation, eliminating the need for pressurized lines, explosives and testing equipment on surface. Operationally, the time savings are substantial. A typical multi-zone abandonment can take up to three days using current technology. The KWAT system will take less than one day for the same well. The minimal footprint vastly improves safety on the pad. Less equipment reduces emissions, keeping the wellsite surface clean while reducing the manpower required for operations compared to conventional operations. If the operator should need to assess a leak in the casing the KWAT will also serve as an assessment tool to find issues in a fraction of the time and cost versus rig based procedures.